Troubleshooting Common Issues with Industrial Scales and How to Fix Them

Troubleshooting Common Issues with Industrial Scales and How to Fix Them

Blog Article

Why to Select Industrial Scales for Accurate Weight Measurement in Various Industries

In an age where accuracy is paramount, the choice of commercial ranges for accurate weight measurement plays an essential role across varied fields. These ranges not only improve functional performance yet likewise make certain compliance with regulative criteria, impacting everything from manufacturing to delivery.

Relevance of Accurate Weight Measurement

In the world of commercial procedures, the value of precise weight dimension can not be overemphasized. Precise weight measurement is foundational across different markets, affecting both functional performance and product quality - Industrial Scales. It works as an important variable in inventory administration, making certain that materials are adequately accounted for, consequently lessening waste and reducing expenses

In production, precise weight dimension straight influences production processes. Anomalies in weight can cause second-rate products or extreme resource allotment, influencing overall earnings. In addition, in industries such as drugs and food production, adherence to stringent weight specs is crucial for regulatory compliance and consumer security.

Furthermore, accurate weight dimensions assist in effective logistics and supply chain management. Effectively evaluated shipments make certain that transportation costs are maximized which inventory degrees are preserved accurately, therefore protecting against stock scarcities or overstock circumstances.

Sorts Of Industrial Scales

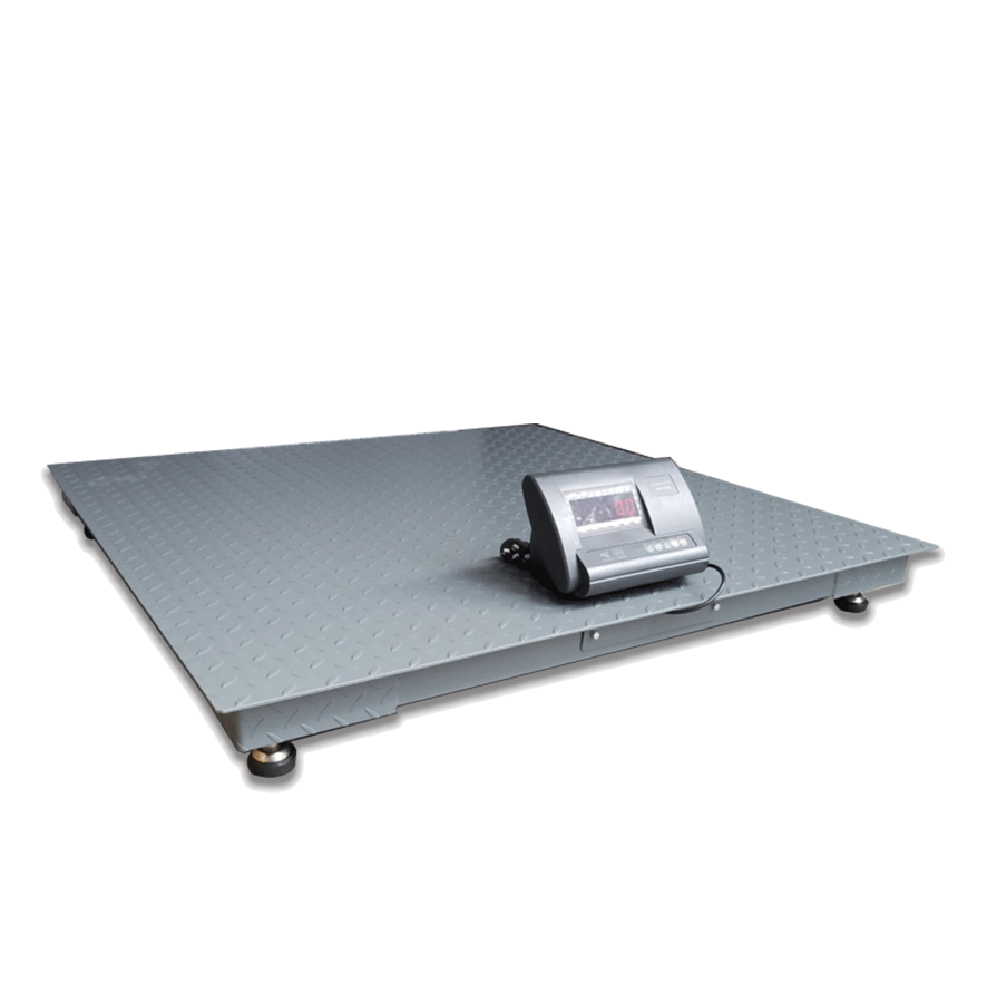

A vast range of industrial scales are readily available, each created to meet details measurement requires across varied industries. Usual types consist of floor ranges, which are suitable and durable for weighing big items or pallets in stockrooms and distribution facilities. Bench ranges are smaller and suitable for lighter materials, usually used in retail setups or making for accurate part control.

An additional category is mobile ranges, which offer the versatility to be relocated conveniently around job sites, making them excellent for field operations or temporary setups. Accuracy ranges, on the other hand, are made for high accuracy and are frequently used in laboratories and high quality control environments.

Lots cells are vital components in numerous industrial scales, transforming force right into an electric signal for precise readings. In addition, vehicle ranges offer the ways to consider hefty cars and their loads, making sure compliance with regulations and optimizing logistics.

Lastly, checkweighers automatically compare the weight of products versus pre-programmed limitations, improving quality control in manufacturing lines (Industrial Scales). Each kind of commercial scale serves a distinct feature, dealing with the particular needs of sectors such as manufacturing, logistics, food handling, and drugs

Advantages of Utilizing Industrial Scales

Consistently utilizing industrial scales provides substantial benefits across various industries. One of the primary benefits is boosted precision in weight dimension, which is essential for maintaining high quality standards and regulative compliance. Accurate measurements protect against costly mistakes in inventory, manufacturing, and shipping management, inevitably resulting in boosted operational efficiency.

Moreover, commercial ranges are designed for sturdiness and robustness, permitting them to stand up to severe atmospheres typically found in production and warehousing. This durability guarantees a lengthy life expectancy, decreasing the demand for regular replacements and upkeep costs.

In addition, using commercial ranges enhances safety and security and minimizes waste. By making certain that products are weighed precisely, business can prevent overwhelming cars, which can cause mishaps and penalties.

Applications Across Various Industries

Industrial scales play a pivotal role in numerous fields, consisting of production, logistics, food processing, and pharmaceuticals. In manufacturing, these ranges are essential for ensuring that basic materials are gauged precisely, like this thus maintaining product top quality and uniformity (Industrial Scales). Precision in weight measurement straight influences production efficiency and price monitoring

In logistics, industrial scales facilitate the exact evaluating of shipments, which is essential for sticking to maximizing and shipping guidelines freight costs. Precise weight information aids streamline procedures and boosts supply chain monitoring.

The food processing industry counts heavily on commercial scales for conformity with health and wellness guidelines. They are used to consider components specifically, making sure that formulations meet both high quality standards and lawful needs. This is necessary not only for customer safety however also for preserving brand name integrity.

Drug firms use commercial scales to guarantee exact dosages in medication manufacturing, where even the tiniest inconsistency can have considerable effects. Conformity with strict regulative criteria makes precise weight measurement essential in this industry.

When Selecting Ranges,## Factors to Think About.

Choosing the right range for details applications requires cautious factor to consider of numerous variables. The capability of the range is vital; it has to accommodate the maximum weight of the items being measured without exceeding its limits. Additionally, the readability, or smallest increment the scale can accurately display, is vital for precision, particularly in industries where weight discrepancies can result in significant financial losses or security worries.

Environmental conditions also play a significant role in scale option. For instance, scales used in read here destructive or humid settings might need specialized products to make sure toughness. In a similar way, mobility might be necessary in specific applications, demanding light-weight and battery-operated designs.

Final Thought

Finally, the option of commercial scales is critical for making sure precise weight dimension throughout varied sectors. Their capacity to give precise readings not only enhances operational efficiency but also supports regulatory compliance and inventory management. The flexibility and toughness of these ranges promote their application in different industries, eventually contributing to cost reduction and boosted item top quality. Hence, spending in top notch commercial scales is vital for organizations aiming to maintain high standards and take full advantage of earnings.

Report this page