A complete walkthrough to deploying an optical measurement system in your facility

A complete walkthrough to deploying an optical measurement system in your facility

Blog Article

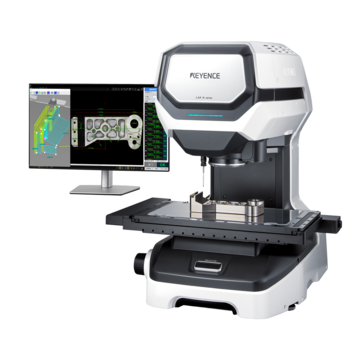

The Role of Optical Dimension Equipments in Advancing Metrology Strategies

Optical dimension systems have changed width, bringing a level of precision that was once inconceivable. As you explore additionally, you'll discover exactly how these systems are forming the future of measurement and quality control.

The Advancement of Width: A Historic Viewpoint

As you discover the background of assessment, you'll find that its evolution reflects humanity's pursuit for accuracy and standardization. From old worlds utilizing body components as systems of dimension to the advancement of standard weights and procedures, each step shows our desire for accuracy. The Egyptians constructed the pyramids using accurate measurements, while the Romans progressed design with their sophisticated measuring devices.

During the Renaissance, clinical advancements changed the emphasis toward more empirical methods, leading the way for modern width. The introduction of the statistics system in the late 18th century noted a considerable turning point, developing global criteria. Throughout the 20th century, technological innovations further transformed width, allowing very exact dimensions in numerous fields.

Today, metrology remains to evolve, integrating digital innovation and automation. This history highlights not simply the relevance of dimension yet also our unrelenting pursuit of enhancing precision and uniformity in our increasingly complicated world.

Principles of Optical Dimension Solutions

Understanding the principles behind optical dimension systems is necessary for exact cause metrology. You'll want to take into consideration fundamental optical concepts, dimension accuracy elements, and effective system calibration strategies. Each of these elements plays an essential duty in ensuring your measurements are trustworthy and exact.

Essential Optical Concepts

While checking out optical measurement systems, you'll encounter fundamental optical principles that create the foundation of precise data acquisition. Light acts in predictable ways, and recognizing these habits-- like refraction, reflection, and diffraction-- is vital for efficient dimensions. You'll utilize lenses and mirrors to adjust light and focus it onto your target, making certain precision in your analyses. Furthermore, the wave nature of light permits interference patterns, which can improve measurement resolution. Polarization can likewise play an essential role in distinct signal from noise, improving the clarity of your results. By understanding these concepts, you'll be equipped to take advantage of optical modern technologies successfully, leading the way for developments in width and ensuring your dimensions are both repeatable and trusted.

Measurement Accuracy Factors

To attain high measurement accuracy in optical systems, a number of factors come into play, influencing the dependability of your outcomes. Top notch lenses and detectors decrease aberrations and noise, ensuring your dimensions are exact. By dealing with these variables, you can enhance the general efficiency of your optical measurement systems, leading to more reputable and precise results in your width applications.

System Calibration Techniques

Attaining high dimension accuracy is only part of the equation; proper system calibration methods are equally important in optical measurement systems. To ensure your system supplies trustworthy outcomes, you need to regularly adjust it utilizing standard recommendation materials. Begin by readjusting the optical elements, like lenses and mirrors, to lessen systematic errors. Next, utilize recognized measurements to verify the system's outcome and make necessary corrections. It's also essential to represent ecological factors-- temperature level and moisture can affect measurements. Execute a routine calibration schedule to preserve uniformity over time. Lastly, document all calibration procedures and outcomes; this will certainly help you track efficiency and address any type of drift in precision. With these strategies, you'll boost the reliability of your optical dimension system.

Trick Technologies Behind Optical Dimension

Optical dimension systems rely upon a number of crucial innovations that boost accuracy and efficiency in assessment. One necessary modern technology is interferometry, which utilizes the interference of light waves to determine tiny variations and surface irregularities with extreme precision. You'll also find laser scanning systems, which catch in-depth 3D information of things swiftly, making them very useful for dimensional analysis.

In Addition, CCD and CMOS sensors play a substantial duty in converting light into electric signals, permitting high-resolution imaging and accurate measurements. Advanced algorithms for picture processing further enhance measurement precision by examining information in real time, removing noise and improving features.

Lastly, optical fiber supply versatility and the capability to gauge in challenging atmospheres while preserving signal integrity. By leveraging these innovations, you can achieve superior lead to your width jobs, making certain that your dimensions are both accurate and trusted.

Applications of Optical Dimension in Industry

As industries significantly require accuracy and performance, the applications of optical dimension systems have ended up being important across various industries. In production, these systems aid you keep an official site eye on dimensions and tolerances in real-time, making certain top quality control without time-consuming hand-operated checks. In the automotive market, optical measurements assist in aligning parts with accuracy, improving safety and security and efficiency.

In electronics, you're making use of optical approaches to examine min features on circuit boards, finding defects that might result in failures. The aerospace field advantages from non-destructive testing methods, enabling you to evaluate materials and components without jeopardizing their integrity.

Optical dimension also plays a crucial duty in textiles, making sure material dimensions meet exact requirements. optical measurement system. With that site their capability to supply high-resolution data rapidly, these systems encourage you to make enlightened decisions, simplify processes, and eventually drive development throughout your industry

Enhancing Precision and Efficiency in Dimensions

When you consider improving precision in measurements, accuracy in your dimension strategies is vital. By enhancing these procedures, you can accomplish quicker outcomes without sacrificing quality. Let's explore exactly how adopting advanced optical measurement systems can raise both precision and effectiveness in your job.

Accuracy in Dimension Techniques

Precision in dimension strategies is crucial for accomplishing dependable results in metrology, especially given that tiny discrepancies can lead to considerable mistakes. By making use of innovative optical measurement systems, you can enhance the precision of your measurements. In enhancement, precise measurements permit you to keep high quality control, making certain that items satisfy strict specs.

Enhancing Dimension Procedures

To boost accuracy and efficiency in measurements, enhancing your measurement processes is vital. Beginning by adopting optical measurement systems that provide real-time data, decreasing the time spent on hand-operated recording. These systems often incorporate effortlessly with existing software, enabling you to automate data collection and evaluation.

Following, systematize your dimension protocols. By carrying out regular procedures, you lessen variability and boost repeatability. Do not forget to consistently calibrate your tools to ensure its precision.

The Influence of Optical Measurement on Study and Growth

As scientists venture to push the limits of technology, optical measurement systems have actually come to be indispensable devices in the growth procedure. These systems supply you with accurate, real-time information that enhances your capacity to analyze intricate products and frameworks. In different fields, from biotechnology to aerospace, you rely upon optical dimensions to boost and maximize styles product efficiency.

With high-resolution imaging and non-contact methods, you can lessen example disruption, permitting more precise outcomes. This capacity to capture minute information accelerates your R&D cycle, letting you useful link repeat layouts promptly and effectively. Additionally, optical measurement promotes collaboration across techniques, as the data produced is usually conveniently interpretable and shareable.

Eventually, incorporating optical dimension systems right into your research not only enhances productivity however likewise deepens your understanding of the phenomena you study. By leveraging these sophisticated strategies, you're better equipped to innovate and stay in advance in a competitive landscape.

Future Trends in Optical Dimension Systems

With the quick innovation of technology, you're likely to see considerable shifts in optical dimension systems that will redefine their application throughout numerous markets. You'll observe a step toward boosted automation and integration of fabricated knowledge, permitting real-time information analysis and improved accuracy. Miniaturization is one more pattern; small devices will allow measurements in tighter spaces, making them suitable for fields like aerospace and biomedical applications.

Expect to see systems that can operate in challenging atmospheres, providing trustworthy measurements in extreme conditions. As these technologies converge, you'll discover that optical dimension systems not only boost precision but also simplify operations, inevitably driving innovation and effectiveness in your projects.

Frequently Asked Questions

Exactly How Do Optical Measurement Solutions Contrast to Typical Measurement Techniques?

Optical measurement systems offer greater precision and faster outcomes compared to traditional methods. You'll find they catch even more data points precisely, lowering human mistake and increasing integrity, making them a recommended choice in numerous applications.

What Industries Advantage Most From Optical Dimension Equipments?

You'll find markets such as aerospace, auto, and electronics benefit most from optical measurement systems. These fields depend on accurate dimensions to ensure high quality and performance, improving effectiveness and reducing expenses via sophisticated technology.

Are Optical Dimension Systems Expensive to Apply?

Optical measurement systems can be costly to apply, but their precision and effectiveness typically warrant the expense. Buying such technology can bring about considerable long-lasting financial savings and improvements in top quality throughout different applications.

What Skills Are Called For to Run Optical Measurement Systems?

To run optical measurement systems, you'll need strong logical abilities, interest to detail, and proficiency in software devices. Knowledge with optics and an understanding of measurement principles will certainly also enhance your performance and effectiveness.

Exactly How Do Ecological Variables Influence Optical Measurements?

Ecological factors like air, moisture, and temperature top quality can distort optical dimensions. You'll observe variations in accuracy due to light interference or refraction. optical measurement systems. Maintaining stable conditions is crucial for trusted and accurate optical dimension results

Final thought

In summary, optical measurement systems are changing metrology by giving unmatched accuracy and effectiveness. As you explore future patterns, you'll see exactly how the assimilation of AI and automation will certainly continue to elevate measurement techniques, driving advancement and boosting top quality control.

Achieving high measurement precision is just component of the equation; proper system calibration strategies are just as essential in optical measurement systems.When you believe concerning boosting accuracy in measurements, precision in your measurement methods is vital. By utilizing innovative optical dimension systems, you can boost the precision of your measurements.To improve accuracy and efficiency in dimensions, streamlining your measurement procedures is vital. Exactly How Do Optical Measurement Equipments Compare to Typical Dimension Techniques?

Report this page